Yagona eksa gidravlik quvurlarni bükme mashinasi

Yagona eksa gidravlik quvurlarni bükme mashinasi avtomatik quvurlarni bükme mashinasi bo'lib, ishchilar quvurlarni egishning turli yo'nalishlariga muhtoj bo'lsa, qo'lda aylanishga muhtoj.

Yagona eksa gidravlik quvurlarni bükme mashinasi

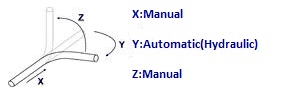

Yagona eksa gidravlik quvurlarni bükme mashinasi avtomatik quvurlarni bükme mashinasi bo'lib, quvurlarni bükmenin turli yo'nalishlari kerak bo'lsa, ishchilarga qo'lda aylanish kerak. Quyidagi rasm sifatida:

Mashinalarning ushbu modeli sensorli ekranli bosimining ko'tarilishi boshqaruvi, yarim avtomatik modellar, gidravlik moy bilan boshqariladi.

Ushbu mashinalar turli xil quvur o'lchamlarini bükme talablari uchun turli xil qoliplarni almashtirishi mumkin.

Ilovalar

Quvurlarni bükme mashinalari quvurlar va quvurlarni bükmeye muhtoj bo'lgan ko'plab ilovalar va sanoat uchun ishlaydi.

Bino konstruktsiyasi (derazalar, trusslar, ichki bezatish)

Mebel (ko'rpa-to'shaklar, kasalxona jihozlari, nogironlar aravachalari)

Avtomobil (egzoz, o'rindiq romlari, stabilizatorlar)

Gimnaziya uchun jihozlar - bolalar aravachalari

Kimyo zavodi - neft-kimyo zavodlari

Materiallarga ishlov berish uskunalari

Ko'rgazma uskunalari do'konlari

Velosiped, mototsikl ramkalari

Elektr jihozlari

Sovutgich quvurlari

Sug'orish tizimlari

Qozon trubkasi

Yagona eksa gidravlik quvurlarni bükme mashinasining parametrlari

Qaysi modellarga shubha qilsangiz, to'g'ridan-to'g'ri biz bilan bog'laning, biz sizning talablaringiz sifatida eng yaxshi quvur bükme mashinasini tavsiya qilamiz.

Yagona eksa gidravlik quvurlarni bükme mashinasining texnik xususiyatlari

Ushbu model turli xil quvur o'lchamlari uchun turli xil qoliplarni almashtirishi mumkin.

- Quvvatli pressdan ko'ra ko'proq energiya tejash uchun gidravlik haydovchi. Qadamsiz bosimni tartibga solish.

- Materiallar uchun po'lat, zanglamaydigan, alyuminiy, titanium va guruch kiradi.

- Silindr tomonidan boshqariladigan bükme o'qi, oziqlantirish o'qi-qo'lda, aylanadigan o'q-qo'lda.

- Mikrokompyuter boshqaruvi, interaktiv PLC sensorli ekrani, qulay ishlash va moslashuvchan sozlamalar.

- Tizim diagnostikasi va bir nechta til imkoniyatlari.

- Dastur tanlashning maksimal 16 to'plami, har bir dastur uchun maksimal 16 bender.

- Dasturlashtiriladigan materiallar har bir egilish burchagi uchun orqaga qaytish sozlamalari.

- Uskunaning yuqori haroratda uzoq vaqt barqaror ishlashini ta'minlash uchun gidravlik sovutish tizimi.

- Yuqori aniqlik. Gantry frezeleme, yuqori aniqlikdagi ishlashni ta'minlash uchun dastgohni zımbalama qoliplari bazasini qayta ishlaydi. Yuqori sifatli temir yo'lni boshqaradi va uzatmalarni uzatadi.

- Rejimni tanlash: Avto/qo‘lda. Favqulodda to'xtash moslamasi bilan jihozlangan.

- Nosozliklarni avtomatik ravishda aniqlash, ko'rinadigan signallar ro'yxati, signalni tiklash.

- Bükme mashinasi uchun 24 oy kafolat, qoliplarni bükme uchun 6 oy.