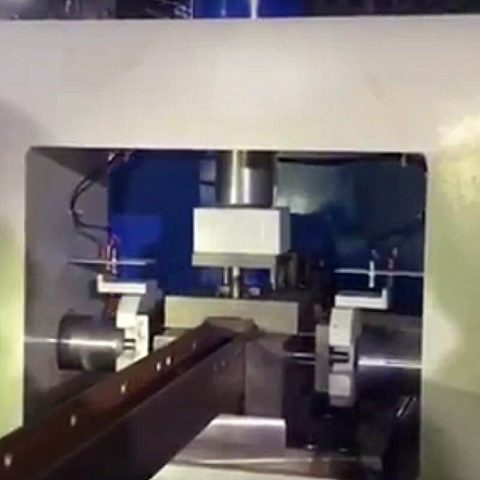

Three Cylinders CNC Fully Automatic Punching Machine

Three Cylinders CNC Fully Automatic Punching Machine can meet the punching requirements which needs 3 holes in different directions on one piece of materials, with the high accuracy requirements.

Three Cylinders CNC Fully Automatic Punching Machine

Three Cylinders CNC Fully Automatic Punching Machine can meet the punching requirements which needs 3 holes in different directions on one piece of materials, with the high accuracy requirements. Its 3 sets of cylinders are placed for punching from the left side, right side, and the upper side of materials.

This model of Industrial hydraulic punching machine performs automatic pulling long length iron pipes, automatic feeding iron pipes, automatic calculating the holes distances, automatic punching materials.

Applications

3 cylinders fully automatic industrial punching machine is used to punch large thickness iron or steel pipes, such as square pipes, round pipes, I-steel, double tee iron, double T-steel, flange beam, h-bar, i-bar.

Available for different shapes of holes punching, including the square hole, rectangular hole, D shape hole, triangular hole, heart hole, oval hole, waist circular hole, prismatic hole, etc.

Video

Parameters

- CE Licence: YES

- Control: CNC, Automatic

- Capacity: 3 holes/second

- Max. materials thickness: 10mm(Thickness enlarge as per requirements)

- Max. materials length: 6000mm As per requirements

- Single Cylinder Max. Punching press: 12Tons, 15Tons, 20Tons, 25Tons

- Whole Machine Max. Hydraulic Press: 36Tons, 45Tons, 60Tons, 75Tons

- Motor Power: 7.5 KW/11KW/15KW/18.5KW

- Voltage: 380-440V 4 Phases 50Hz Customized

- Pneumatic pressure: 5-8bar

- Dimensions: 6800x1000x1700mm

- Net Weight: Around 2000 Kgs

- Available Materials: Square pipes, round pipes, I-steel, double tee iron, double T-steel, flange beam, H-bar, I-bar.

Specifications of Three Cylinders CNC Fully Automatic Punching Machine

Three Cylinders CNC Fully Automatic Punching Machine is available for PLC system, numerical control with LED touchscreen. Reasonable design punch and dies sets, use high quality dies steel.

Gantry milling process the machine punching molds base to ensure high precision performance. Powerful hydraulic unit with forced cooling system

- Reasonable designing punch and dies sets to prevent scratch on dies, auto wiping system removes metal filings.

- 3 cylinders, punch 3 holes at one action.

- High precision. Gantry milling process the machine punching molds base to ensure high precision performance.

- High quality guides rail and transmits gear.

- Available for the different distances of holes punching, by setting on the touchscreen. Automatic numerical control for saving manpower.

- Hydraulic driven, step-less pressure regulation.

- Mode selection: Auto/Manual.

- PLC control, time setting, and pressure adjusting.

- Touchscreen, visible digital display, full processes monitoring.

- Automatically detect malfunctions, visible alarm list, alarm reset.

- 24 months warranty for punching machine, 6 months for punch and dies sets.