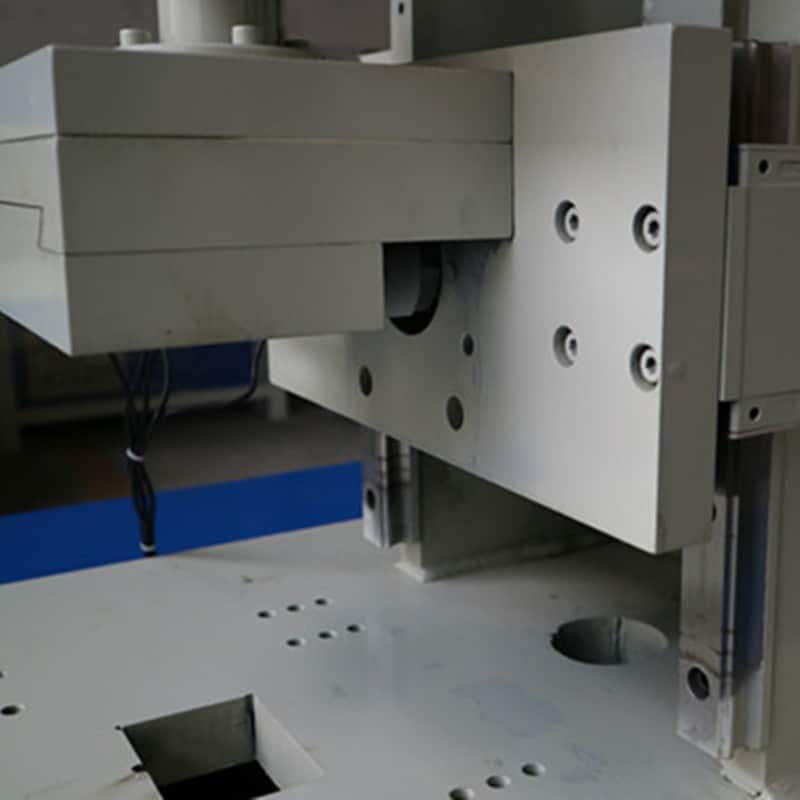

Hydraulic Square Tube Right Angle Notching Machine

Hydraulic Square Tube Right Angle Notching Machine is a customized notching machine, driven by hydraulic power, manual feeding steel pipes by workers. Right angle notching machine is workable for to notch steel tube, stainless steel tube, iron pipes, aluminum alloy, to bend the different angle.

Hydraulic Square Tube Right Angle Notching Machine

Hydraulic Square Tube Right Angle Notching Machine is a customized notching machine, driven by hydraulic power, manual feeding steel pipes by workers. 90° notching machine is workable for to notch steel tube, stainless steel tube, iron pipes, aluminum alloy, to bend a different angle.

Several notches and dies sets can work on one hydraulic notching machine, this notching equipment is customized as needs for different metal notch purposes. This hydraulic notching machine adopts a powerful hydraulic cylinder with 80mm, and 140mm cylinder diameter.

Applications

- This notching machine is workable for notching for aluminum ladders profiles, steel guardrail, zinc steel fence, iron guard fence, aluminum alloy shelf bracket, handrail, balustrade, railing, banisters.

- Available for different materials, including aluminum profile, stainless steel tube, mild steel pipes, iron pipes, copper tube, etc.

Video

Parameters of Hydraulic Square Tube Right Angle Notching Machine

- CE Licence: YES

- Control: Electric

- Capacity: 40 actions/min

- Accuracy: ±0.05mm

- Quantity of notching molds: 1 Set

- Driven power: Hydraulic

- Motor power: 5.5KW

- Net weight: About 600Kgs

- Dimensions: 1000x800x1600mm

- Voltage: 100-240V /380-415V 3 Phases/ 50/60Hz Customized

- Available materials: Stainless steel tube, Mild Steel Pipe, Iron Pipe, Aluminum profile, etc.

Specifications

It is available for different notching molds. Reasonable design notch and dies sets, to prevent scratch on the tube surface. Gantry milling process the machine punching molds base to ensure high precision performance. notching power is driven by the hydraulic unit with an auto-cooling system. This machinery is a manual notching machine which available for the most convenient operation and economic consideration.

- No scratch on the surface of metal tube and pipes, reasonable designing notch and dies sets to preventing scratch, auto wiping system removes metal filings.

- High precision. Gantry milling process the machine punching molds base to ensure high precision performance. High-quality guides rail and transmits gear.

- Available for the different distances of holes notching.

- Hydraulic-driven, step-less pressure regulation.

- One set of notching machines is workable for different shapes of holes notching, by replacing customized notch and dies sets.

- Manual feed for easy maintenance and cheap notching machine consideration.

- Durable hydraulic cylinder, best quality hydraulic hose.

- notch and dies sets were made by SKD11 with a temper.

- 24 months warranty for notching machine, 6 months for notch and dies sets.